15 Aug What Tool is Used to Cut Metal?

Metals have been around for centuries, and over time, humans have discovered various ways to shape, resize, or cut metal using different cutting tools. These tools have been developed and improved over time, from the simple chisels and hammers used by ancient craftsmen to the modern, sophisticated tools like laser cutters and plasma cutting machines used in the industrial world. However, despite the numerous cutting tools available, there is still one question that many individuals ask when it comes to cutting metals: “What tool is used to cut metal?” In this article, we will explore the different tools used to cut metal, their pros and cons, and their applications in various industries.

Manual Metal Cutting Tools

Manual metal cutting tools are some of the oldest cutting tools used to cut metals. These tools are mostly handheld, and their mechanisms include shear-type, guillotine-type, and saw-type cutters.

Shear-Type Metal Cutters

Shear-type metal cutters are manual cutting tools that work by shearing the metal between two blades. They are mostly used for cutting thin and soft metals, including copper, brass, and aluminum. If you’re looking to discover how to cut metal closet rod, shear-type cutters may not be the best tool for the job. However, if you’re working with softer metals, the blades of shear-type cutters are made of high-quality tool steel that is hardened to give them the necessary strength and durability for cutting.

Guillotine-Type Metal Cutters

Guillotine-type metal cutters are manual cutting tools with a fixed blade and a long handle. These tools are designed for cutting sheets of metal, and they work by clamping the metal to be cut between the blade and a fixed backstop. The long handle provides the necessary leverage for cutting through the metal easily.

Saw-Type Metal Cutters

Saw-type metal cutters are manual cutting tools that use a blade with small, sharp teeth to cut through metal. These tools are ideal for cutting hard and thick metals, including steel and cast iron. The blade of a saw-type metal cutter is usually made of high-speed steel, tungsten carbide, or diamond.

Power Metal Cutting Tools

Power metal cutting tools are mechanized cutting tools that use electric or hydraulic power to cut through metal. These tools are faster and more efficient than manual metal cutting tools and are ideal for cutting large and thick pieces of metal.

Angle Grinders

Angle grinders are power metal cutting tools that are handheld and use a powerful motor to rotate an abrasive disc at high speed. These tools are ideal for cutting and grinding metals like steel and aluminum. The abrasive disc of an angle grinder can be changed to suit different cutting or grinding applications.

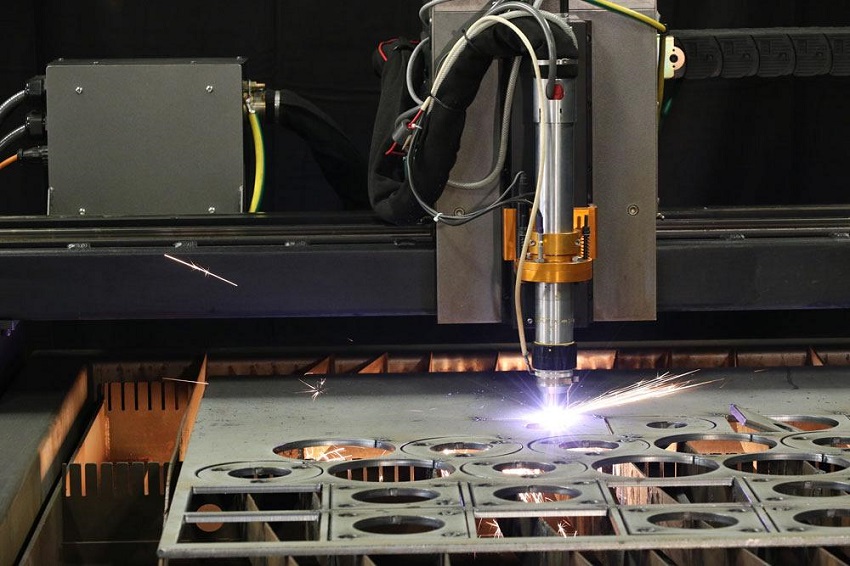

Plasma Cutters

Plasma cutters are power metal cutting tools that use a high-velocity jet of ionized gas to cut through metal. These tools are ideal for cutting metals that are too thick for other cutting tools, including steel, iron, and aluminum. Plasma cutting is also unique because it can cut through non-ferrous metals like copper and brass.

Laser Cutters

Laser cutters are power metal cutting tools that use a high-powered laser beam to cut through metal. These tools are highly accurate and precise, making them ideal for cutting intricate designs and shapes. Laser cutting is mostly used in the industrial world for cutting metals like steel, aluminum, and copper.

Conclusion

In conclusion, various cutting tools are used to cut metal, each with its unique application, pros, and cons. Manual metal cutting tools are suitable for cutting thin and soft metals, while power metal cutting tools are ideal for cutting thick and hard metals. The choice of the cutting tool to use depends on several factors, including the type of metal being cut, the thickness of the metal, and the desired outcome of the cutting process. It is always essential to ensure that the chosen metal cutting tool is of the correct size, shape, and type to prevent damage to both the tool and the metal being cut.

FAQs

- What is the best tool for cutting metal?

It all depends on the type and thickness of the metal being cut, as well as the desired outcome. Saw-type cutters are ideal for cutting hard and thick metals, while shear-type cutters are suitable for thin and soft metals.

- How do I choose the right cutting tool for cutting metal?

Consider the type, size, and thickness of the metal, as well as the desired outcome. Also, consider the availability, efficiency, and cost of the cutting tool.

- Is it possible to cut metal without a cutting tool?

Yes, but it is tedious and time-consuming. The most common method of cutting metal without a cutting tool involves using a hacksaw or a file.

- What is the danger of cutting metal?

Cutting metal poses several risks, including injury from flying debris and sharp edges. It is essential to wear protective gear like gloves, eye protection, and face shields.

- Can I use a saw blade on an angle grinder?

No. Saw blades are designed to be used on saws, while angle grinders use abrasive discs. Using a saw blade on an angle grinder can result in serious injury or damage to both the tool and the operator.

Sorry, the comment form is closed at this time.